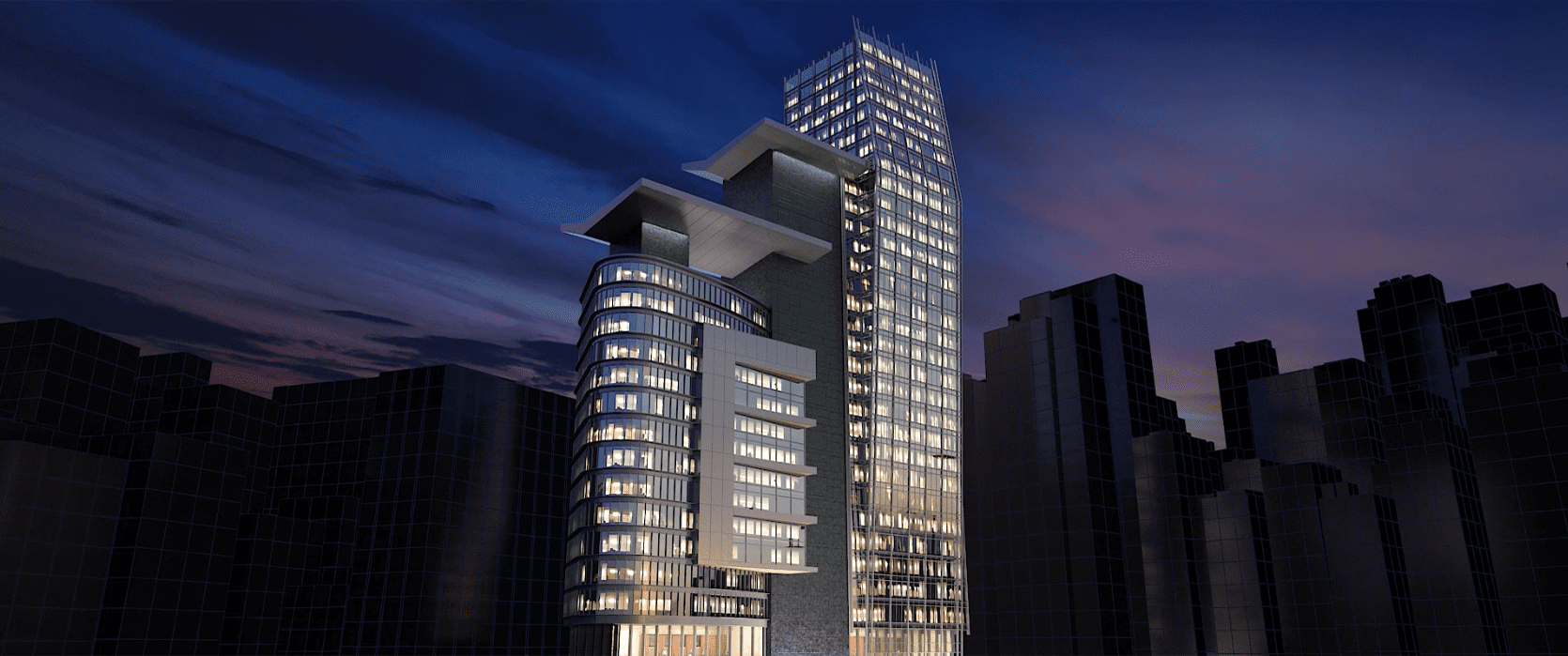

Prototype Office Building

Project Mercury is LIFTbuild’s prototypical office facility. This LIFTbuild office building consists of slip-formed structural spines and steel-framed floorplates assembled at-grade and then lifted and locked into their final location. All building systems are installed at-grade prior to the lifting operation. Interior buildout is completed at final location in an environmentally controlled space. Our team worked with the client to the viability phase of this project.