TRANSFORMING HOW THE WORLD IS BUILT

To achieve the necessary delivery performance improvements, our approach transforms four key areas: Supply Chain, Manufacturing Logistics, Product Design, and Assembly Process. All of these are engaged and leveraged through our delivery process.

All of these areas are engaged and leveraged within our program delivery process. Globally, construction labor-productivity growth averaged 1% per year over the past two decades, compared with 2.8% for the world economy and 3.6% for manufacturing. In the United States, since 1945, while productivity in manufacturing, retail and agriculture has grown by 1,500%, construction’s increase has been negligible.

Examples of innovation suggest that enabling seven areas simultaneously could boost productivity by 50 to 60 percent (McKinsey, “Route to Higher Productivity,” 2017). They are:

- Reshape regulation

- Rewire the contractual framework to reshape industry dynamics

- Rethink design and engineering processes

- Improve procurement and supply-chain management

- Improve on-site execution

- Infuse digital technology, new materials, and advanced automation

- Reskill the workforce

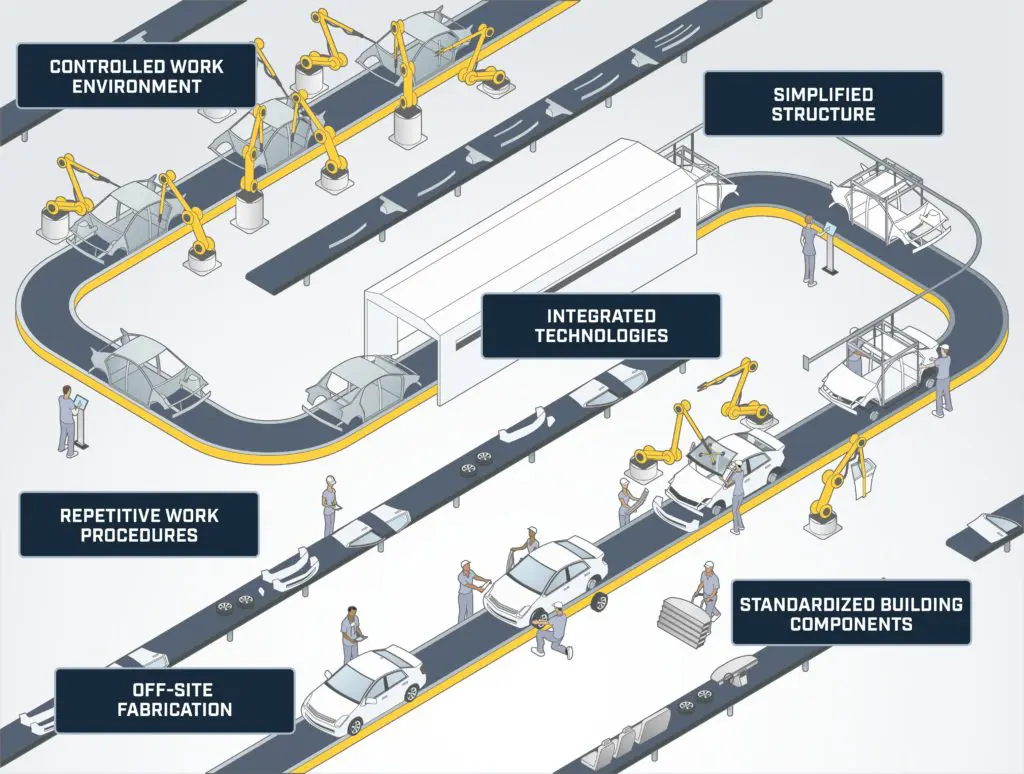

Rethinking Construction: Utilizing a Manufacturing Approach

LIFTbuild utilizes patented approaches to the assembly process of Vertical Manufacturing℠. The building structure consists of concrete structural spines and steel-framed decks for roofs and floors. All roof and floor plate assembly is done at ground level. Once the floor plates have been assembled, the exterior facade and selected systems are installed.

Prefabricated sub-assemblies are placed prior to the completed floor plate assembly being raised and locked into its final position. The fit-out is accomplished in a fully-enclosed and conditioned space while the floors below continue to be built. This maximizes potential savings on schedule and budget while providing a safe and productive work environment. Click here to learn more about our process in Modern Steel Construction Magazine.